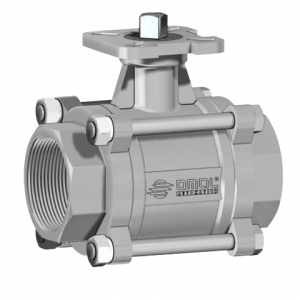

The valve incorporates key features for optimal functionality. Firstly, it adopts the EN ISO 5211 top mounting system, facilitating easy coupling with a variety of drives for seamless integration. Secondly, the inclusion of three guiding bushings on the shaft ensures precise alignment with the body, preventing oscillations even under high pressure conditions. This design not only minimizes friction between the shaft and body but also enhances overall stability.

The valve boasts several general features that enhance its functionality and versatility. Its three-piece construction facilitates easy replacement, making it particularly suitable for plants requiring frequent maintenance. The threaded ends adhere to ISO 7/1 specifications, providing compatibility with various connection methods such as socket welding and butt welding. The valve is equipped with standard PTFE seals, ensuring reliable sealing performance. With a wide working temperature range from -20°C to +180°C, as indicated in the provided diagram, the valve accommodates diverse operating conditions.

The design incorporates energized and self-lubricated strips, resulting in reduced friction between the piston and cylinder. This feature not only minimizes friction but also prevents the bonding of the seal to the cylinder, even after extended periods of inactivity. Additionally, the use of steel for slots, bushes, and pins with a hardness exceeding 50 HRC enhances the actuator’s resistance to internal forces. Moreover, the implementation of rolling friction between the piston and slot contributes to further friction reduction, promoting smoother operation within the system. These elements collectively ensure enhanced durability, efficient performance, and prolonged functionality of the actuator.

TECHNICAL FEATURES

Actuator ON-OFF; working angle 90° (100° Max.).

Service 50%

Maximum torque from 10 to 1960 Nm. (see the table)

Supply voltage 230 Vac (±10%) 50/60 Hz 1Ph

Insulation resistance 100 M /500 Vdc

Tension insulation 1500 Vac/1 minute

Motor with Class E insulation

Working temperature from –25°C to + 55°C (for use in temperatures below

GENERAL FEATURES:

Threaded valve ends, as per EN 10226-1 Rp (ex ISO 7/1) for Ares valves; ISO 228/1 for Zeus valves. Other types available on request.

Assembling is possible in all positions: upright, flat or angled.

Range available from 3/8” to 2” in the Double Acting versions, Spring Return N.C. from above and below the plug, Spring Return N.O. from below the plug.

According to 2014/68/EU “PED”.

2014/34/EU ATEX configuration to request at time of order.

The valve features an internal diameter that matches the diameter of the pipe, ensuring high flow capacity. Additionally, it incorporates a pneumatic actuator within the valve, resulting in significant space savings (up to 60%) and reduced costs when compared to an automated valve setup. The piston is equipped with chemical nickel plating (20-25 microns), leading to lower wear of the seals due to increased surface hardness (400-550 HV). The utilization of lip seals further minimizes wear compared to traditional o-ring seals, and the availability of various seal materials enhances compatibility with different types of fluids, depending on the specific seals employed. This combination of features contributes to an efficient and cost-effective valve solution for diverse applications.

Subscribe to our Newsletters

Copyright © 2024 All Rights Reserved.

Website Maintained by Lambourn Digital